Technologies

Asahi Intecc’s four core technologies form

the foundation of our original materials processing technologies.

Over a more than 40-year span, these technologies were developed by us while responding to the sophisticated requirements of our clients, combining them to create many custom high-performance medical components.

Wire

drawing

Wire

forming

Coating

technologies

Torque

technologies

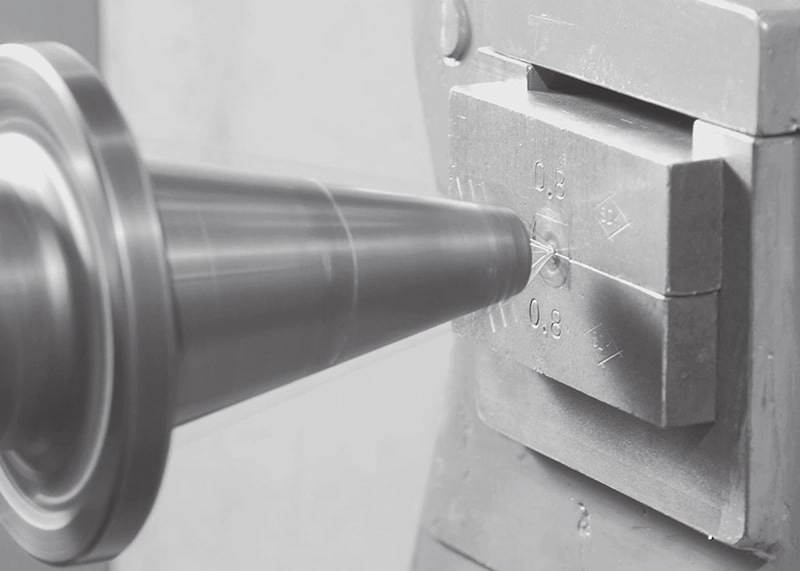

Wire drawing

Asahi Intecc’s high-precision wire drawing technology lies at the core of our medical device components. A key part of the wire drawing technology is maintaining the precision of the ‘die’. Even though the hole section of the die is made of diamond, it gradually wears off with use. In order to maintain the precision of the shape of the die, Asahi Intecc has introduced a high-precision die shape inspection device to measure the center hole of the die at an accuracy of a few thousandths of a millimeter. Through rigorous management of the wire drawing process, high-precision parts can be achieved.

Wire forming

Asahi Intecc’s wire forming technology is applied to produce different types of micro ropes, cable tubes and coils. Besides this, the technology is used for different types of (micro-)catheters, in the form of wire braiding. This braiding increases the strength and torsional rigidity of catheters by weaving wires with a diameter of 30 to 60 μm, and embedding them into polymer-based catheters).

Coating

Asahi Intecc Co., Ltd. has a large portfolio of polymer coatings available for medical devices in a wide range of applications. These are supplied both as coatings for our stainless steel products, as well as stand-alone polymer tubing. When it comes to extrusion moulding, there are many types of tubing such as single-layer, multi-layer, multi-lumen and multi-fl exible tubing. We offer extruded tubing at high accuracy according to the needs of customers.

Torque Technology

Asahi Intecc’s medical devices are highly evaluated in the market due to their excellent torsional rotation capabilities. This is made possible by Asahi Intecc’s own processing equipment and propietary torque technologies, which imbues the wire with an ideal degree of this quality. We apply these technologies onto our guide wires, catheters and many other component products to realize advanced operability.

Product Development

With a basic policy of investing at least 10% of sales into R&D expenses, we continue to develop products while maintaining close ties to the medical front.

Since its founding, our R&D-type company group has positioned R&D activities as one of the most important management matters.

Production System

We promote low-cost operations through a mass production system at our overseas manufacturing bases.

In order to accurately respond to the needs of our clients, Asahi Intecc aims for powerful R&D capabilities and advanced mass production technologies through the fusion of R&D and production technologies. The Thai Factory, Hanoi Factory and Cebu Factory serve as the mass production bases. Several thousand excellent staff are working at these dedicated medical factories where quality control systems based on ISO and the latest facilities are introduced.

As production bases of medical devices which deal with precious human life, high-level air checks are implemented at the working spaces to maintain a clean environment. A strict inspection system is put in place at the production lines which includes load inspection of products and micron-level checks of curves and lubricity of wires. Only products that have passed these strict quality control tests are sent into the market.

asahi intecc thailand co., ltd.

(Thai Factory)

asahi intecc hanoi co., ltd.

(Hanoi Factory)

toyoflex cebu corporation

(Cebu Factory)

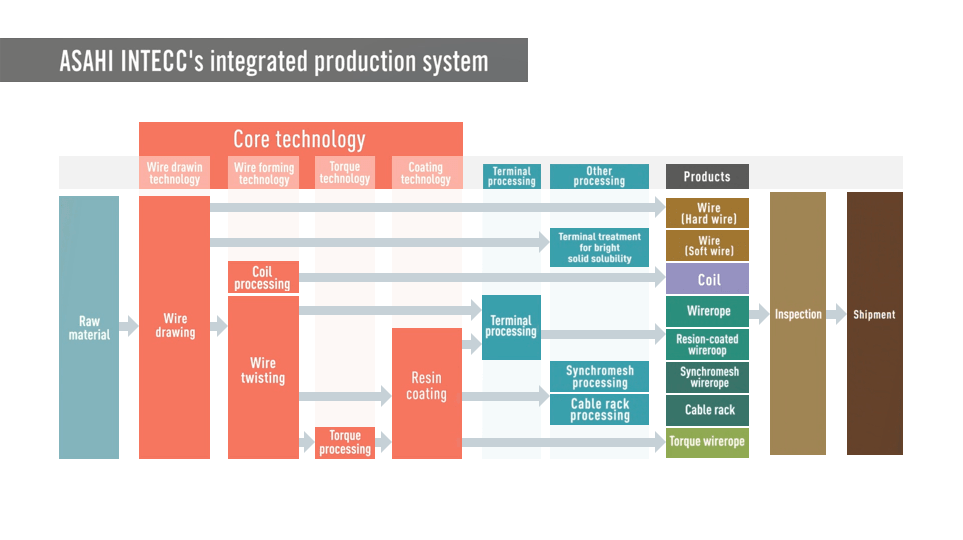

Integrated Production System

Based on our core technologies, the Asahi Intecc Group has its own integrated production system, working from materials all the way to the finished products. Materials used for medical devices require specification and quality of extremely high precision. There are only a limited number of material providers even globally that can stably provide materials that meet these high standards.

Contact

If you have any questions to us,

please feel free to use the following form to submit an inquiry.

Please note before submitting the form