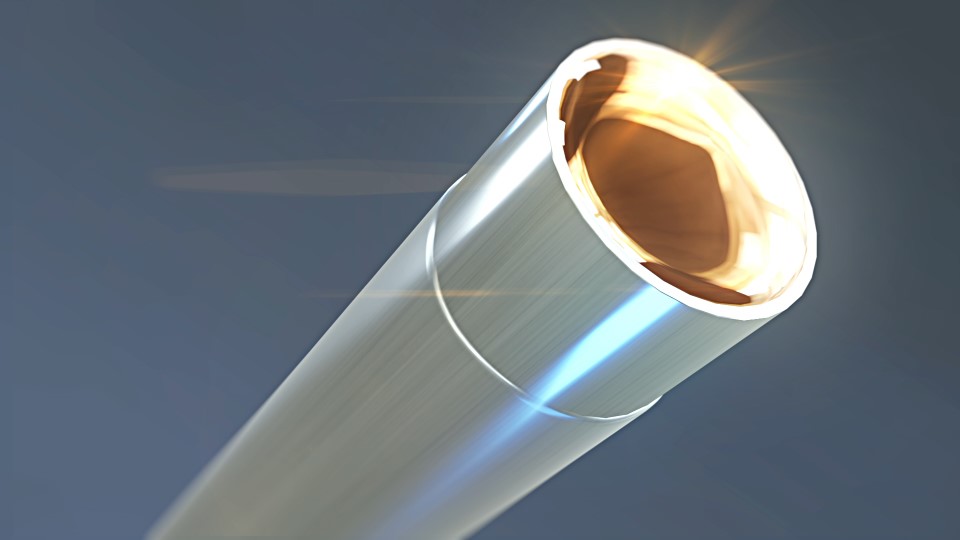

A 0.0003" PTFE liner wall for a maximum of inner catheter lumen

The Asahi PTFE catheter liner features an ultra-thin wall (0.0003"), maximizing the lumen potential of your catheter device for smooth delivery.

The continuous-spooled process on the silver-plated copper-core mandrel completes the streamlining.

Reduce the cost significantly through the entire catheter assembly process with the Asahi PTFE catheter liner.

Are you having difficulties with catheter liner?

Do coating thickness inconsistencies make your manufacturing difficult?

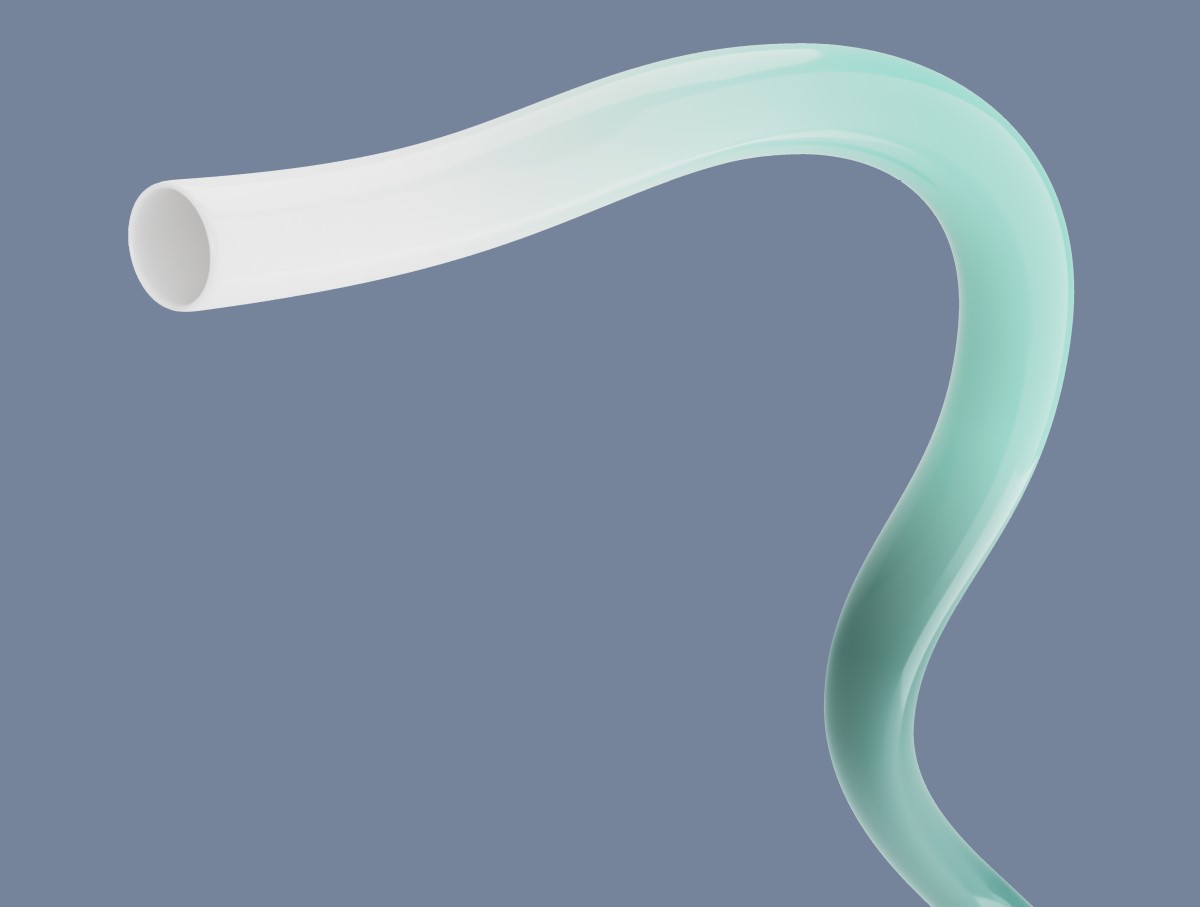

Do you need a thinner catheter liner to increase space and ensure a smooth delivery?

Our innovative process realizes an ultra-thin wall and maximizes consistency.

The continuous spooling process realizes a liner with an ultra-thin wall with tight tolerances, both maximizing the ID and minimizing the OD of your catheter.

A streamlined process for your catheter manufacturing, which minimizes labor, can be more easily validated and is less susceptible to lot-to-lot variations.

How we make it come true?

Our manufacturing process dips a silver-plated copper-core mandrel through a PTFE emulsion, realizing both streamlining and cost reduction through the entire catheter assembly process.

To control quality, we monitor the outer diameter and check the pinhole over the entire length of the manufacturing.

Product specifications

- Ultra thin wall: 0.0003” - 0.0005” (8μm - 13μm)

- Wall tolerance: ±0.00008” (±2μm)

- Inside diameter: 0.01” - 0.11” (0.3mm - 2.8mm)

- Excellent lubricity and chemical resistance.

- Supplied on spool with silver-plated copper-core mandrel (lengths up to 1500 meter)

For more information please see below.

Optional Tie layer enhances Adhesion

- PTFE liner can be supplied with etched or a thin thermoplastic Tie layer (8μm) to enhance adhesion.

- The option of cut lengths or continuous-spooled lengths is available.

Other options

- We can produce PTFE lined tubing with reinforcements such as coil and braided

with material including SS304, tungsten, polymeric filaments such as 66PA, or PEEK.

- Outer jacketing is also available in a variety of materials including Nylon,

polyurethane, HDPE, LDPE, or numerous other materials.

Follow us on LinkedIn